TPE specific silicone masterbatch is PP/PE – carrier silicone masterbatch introduced by Xiangxi. It is dedicated to TPE, TPV, TPR field materials to improve the feel and reduce the role of cohesion, improve production efficiency and stability, to solve the problem of finished product mold mouth accumulation of material, reduce the torque, internal & external lubrication, and improve the surface of the anti-dust.

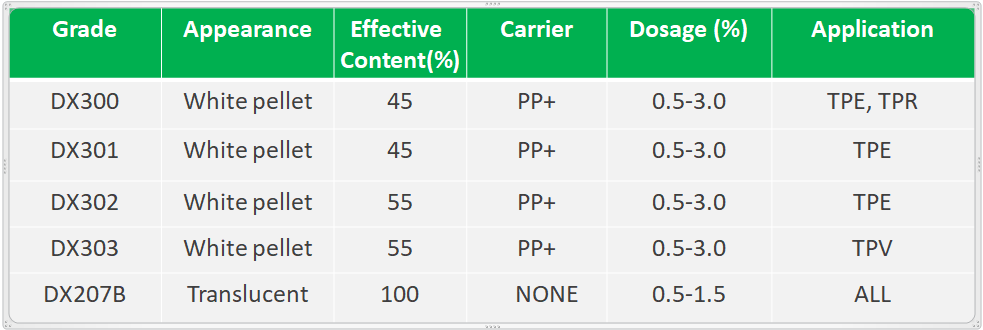

Xiangxi Silicone Masterbatch Additives for TPE Compounds are pelletized formulation with 40- 55% ultra high molecular weight siloxane polymer dispersed in Polypropylene (PP). This material is mainly applied in TPE (Thermoplastic Elastomer) soft gel systems, in polymer processing, it demonstrates superior dispersibility and compatibility, with a minimal impact on the mechanical properties of the material. During highly filled compounding, it can function as an internal lubricating agent.

Sample packaging: Ziplock bag

Finished product packaging:25KG per bag

Stored in a cool and dry place, unopened at room temperature, the product is valid for 12 months.

Non-flammable, transported as conventional chemicals.

For further inquiries, please contact Amy Chan at sales@xiangxichemicals.com

We will contact you within 12 hours, please pay attention to the email sales@xiangxichemicals.com